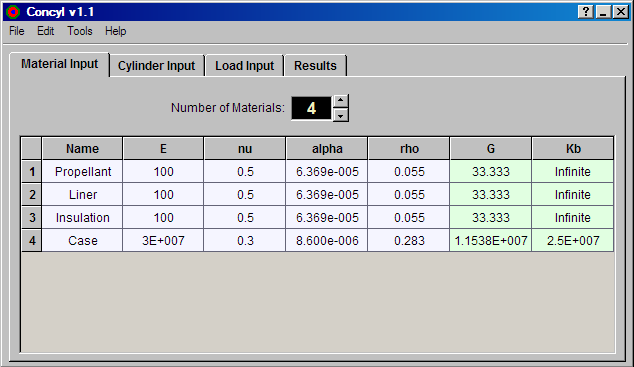

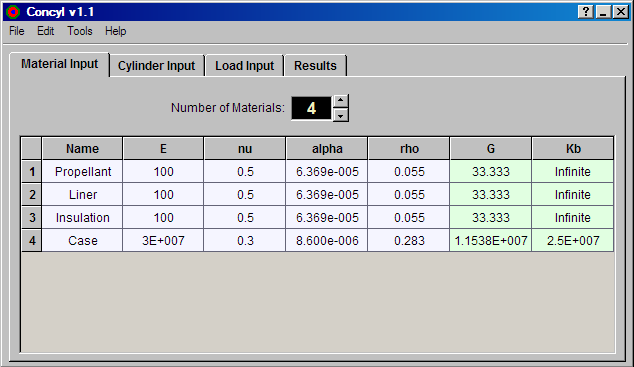

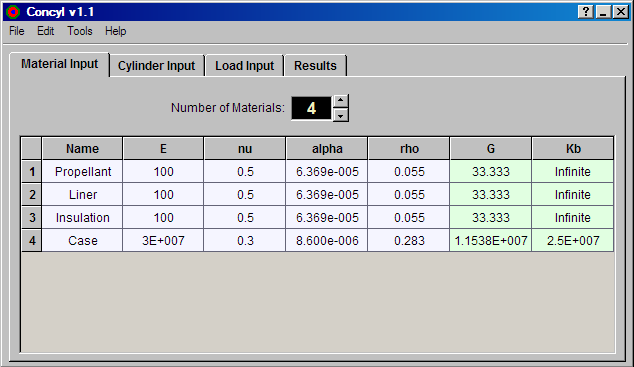

The first tab on the GUI gives the material definition page. A minimum of one material must be

defined to obtain a solution. Any number of materials can be defined, even if all of the materials

are not actually used in cylinder definitions. Each material definition requires five input

parameters: the name, elastic modulus, Poisson ratio, thermal expansion coefficient (CTE), and

density. The name for each material must be unique and can have up to 10 characters. The

computed shear modulus and bulk modulus for each material are also displayed. Figure 5 shows

the material dialog page. Click on the figure for additional information.

Figure 5. Material Definition Dialog Page

An isotropic material requires only two mechanical properties to define its elastic behavior. The

two properties required by Concyl are the elastic modulus and the Poisson ratio. The other

required material properties are the CTE and the density. The CTE relates the thermal strain to

the applied temperature, and the density is used to compute the cylinder mass. The table below

summarizes the properties required to define each material and the base units for each property.

Table 1. Required Material Input

|

Parameter

|

GUI Name

|

Units

|

Example Units

|

|

Elastic Modulus

|

E

|

F/L2

|

psi, Pa

|

|

Poisson Ratio

|

nu

|

unitless

|

-

|

|

CTE

|

Alpha

|

Temp-1

|

/°F, /°C

|

|

Density

|

rho

|

M/L3

|

lb/in3, kg/m3

|

Applicable Base Units:

F = force

M = mass

L = length

H = temperature

T = time

For isotropic materials, the shear modulus (G) and bulk modulus (K) are related to the elastic

modulus (E) and Poisson ratio (n) by the following formulas:

,

,

These formulas reveal that the Poisson ratio has an allowable range of -1 to 0.5. The 0 value

corresponds to a perfectly compressible material, and the 0.5 value corresponds to a perfectly

incompressible material.

The user can choose any units when entering the material properties. However, great care must

be taken to ensure that the material property units are mutually consistent and also consistent

with the units used to specify the applied loads. For example, if the elastic modulus units are psi,

then the density units must be lb/in3, and the applied pressure load units must also be psi.

Likewise, the radial dimensions of the cylinders must be entered in inches for consistency.